Stanford University chemists have developed a practical, low-cost way to permanently remove atmospheric carbon dioxide, the main driver of global warming and climate change.

The new process uses heat to transform common minerals into materials that spontaneously pull carbon from the atmosphere and permanently sequester it. These reactive materials can be produced in conventional kilns, like those used to make cement.

“The Earth has an inexhaustible supply of minerals that are capable of removing CO2 from the atmosphere, but they just don’t react fast enough on their own to counteract human greenhouse gas emissions,” said Matthew Kanan, a Stanford professor of chemistry and senior author of the new study in Nature. “Our work solves this problem in a way that we think is uniquely scalable.”

In nature, common minerals called silicates react with water and atmospheric CO2 to form stable bicarbonate ions and solid carbonate minerals – a process known as weathering. However, this reaction can take hundreds to thousands of years to complete. Since the 1990s, scientists have been searching for ways to make rocks absorb carbon dioxide more rapidly through enhanced weathering techniques.

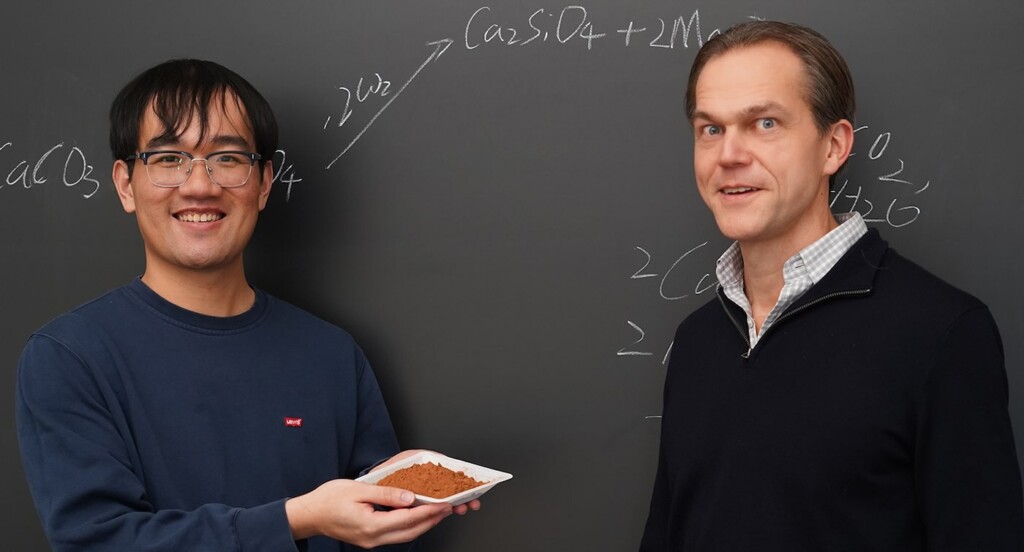

Kanan and Stanford postdoctoral scholar Yuxuan Chen developed a new process for converting slow-weathering silicates into much more reactive minerals that capture and store atmospheric carbon quickly.

“We envisioned a new chemistry to activate the inert silicate minerals through a simple ion-exchange reaction,” explained Chen. “We didn’t expect that it would work as well as it does.”

One of the technologies experts say could prevent additional global warming is carbon-capture through the air—but so far, they remain costly, energy-intensive, or both—by using panels or large fans to drive air through chemical or other processes to remove CO2.

“Our process would require less than half the energy used by leading direct air capture technologies, and we think we can be very competitive from a cost point of view,” said Kanan.

Inspired by a centuries-old technique for making cement

Cement production begins by converting limestone to calcium oxide in a kiln heated to about 1,400 degrees Celsius. The calcium oxide is then mixed with sand to produce a key ingredient in cement.

The Stanford team used a similar process in their laboratory furnace, but instead of sand, they combined calcium oxide with another mineral containing magnesium and silicate ions. When heated, the two minerals swapped ions and transformed into magnesium oxide and calcium silicate – two alkaline minerals that react quickly with acidic CO2 in the air.

As a quick test of reactivity at room temperature, the calcium silicate and magnesium oxide were exposed to water and pure CO2. Within two hours, both materials completely transformed into new carbonate minerals—with carbon from CO2 trapped inside.

For a more realistic test, wet samples of calcium silicate and magnesium oxide were exposed directly to air, which has a much lower concentration of CO2 than pure CO2 from a tank. In this experiment, the carbonation process took weeks to months to occur, still thousands of times faster than natural weathering.

Capturing CO2 in this way could also help farmers

“You can imagine spreading magnesium oxide and calcium silicate over large land areas to remove CO2 from ambient air,” Kanan said. “One exciting application that we’re testing now is adding them to agricultural soil. As they weather, the minerals transform into bicarbonates that can move through the soil and end up permanently stored in the ocean.”

Kanan said this approach could have co-benefits for farmers, who typically add calcium carbonate to soil to increase the pH if it’s too low – a process called liming.

“Adding our product would eliminate the need for liming, since both mineral components are alkaline,” he explained.

“In addition, as calcium silicate weathers, it releases silicon to the soil in a form that the plants can take up, which can improve crop yields and resilience. Ideally, farmers would pay for these minerals because they’re beneficial to farm productivity and the health of the soil – and as a bonus, there’s the carbon removal.”

Using mining sites worldwide

Currently, Kanan’s lab can produce only 15 kilograms (33 pounds) of material a week. But the same kiln designs now used to make cement could produce the amount of materials needed to tackle CO2 because of the abundant magnesium silicates (such as olivine or serpentine), which is found in California, the Balkans, and many other regions. These are also common leftover materials – or tailings – from mining.

“Each year, more than 400 million tons of mine tailings with suitable silicates are generated worldwide, providing a potentially large source of raw material,” Chen said. “It’s estimated that there are more than 100,000 gigatons of olivine and serpentine reserves on Earth, enough to permanently remove far more CO2 than humans have ever emitted.” (A gigaton equals 1 billion metric tons, or about 1.1 billion tons.)

SEE MORE CARBON CAPTURE GOOD NEWS:

• New Wyoming Carbon Capture Project Will Eliminate 5 Mil Tons of CO2 per Year

• UK’s Largest Carbon Capture Project Will Turn 40,000 Tons of CO2 into Baking Soda

• Growth in Carbon Capture Projects is Dramatic, Showing Global Determination to Cut Emissions

After accounting for emissions associated with burning natural gas or biofuel to power the kilns, the researchers estimate each ton of reactive material could remove one ton of carbon dioxide from the atmosphere.

The team is also developing kilns that run on electricity instead of burning fossil fuels—and a grant is already funding their efforts to move the research into practical applications.

(Source: Stanford Report) – SHARE THEIR BREAKTHROUGH On Social Media…